Reference Charts

KWIK-THRED SELF-CLINCHING STUDS

Primary application for this product are panel-to-panel, usually metal, but they are also very good with printed circuit boards (PCB). A hole is pierced into the PCB and the unit it is attached to. The Kwik-Thred stud is inserted using a hand press or by hand, applying parallel squeezing forces. A hex nut is then twisted onto the stud, securing the assembly from the back. As the hex nut is tightened, the serrated stud head grips the front panel to secure the application from the front as well, eliminating the need for welding. Any type ductile material is a good application for Kwik-Thred.

INSTALLATION

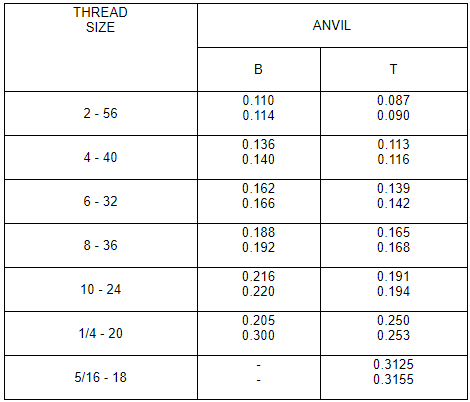

Anvil Dimensions (Inch)

As the application force is applied, part of the sheet cold flows into an undercut under the head, making the fastener an integral part of the sheet.

The many areas in which this type of fastener can be used includes electronics, business machines, appliances, automotive, medical and aircraft.

Why Crescent for Self-Clinching Studs?

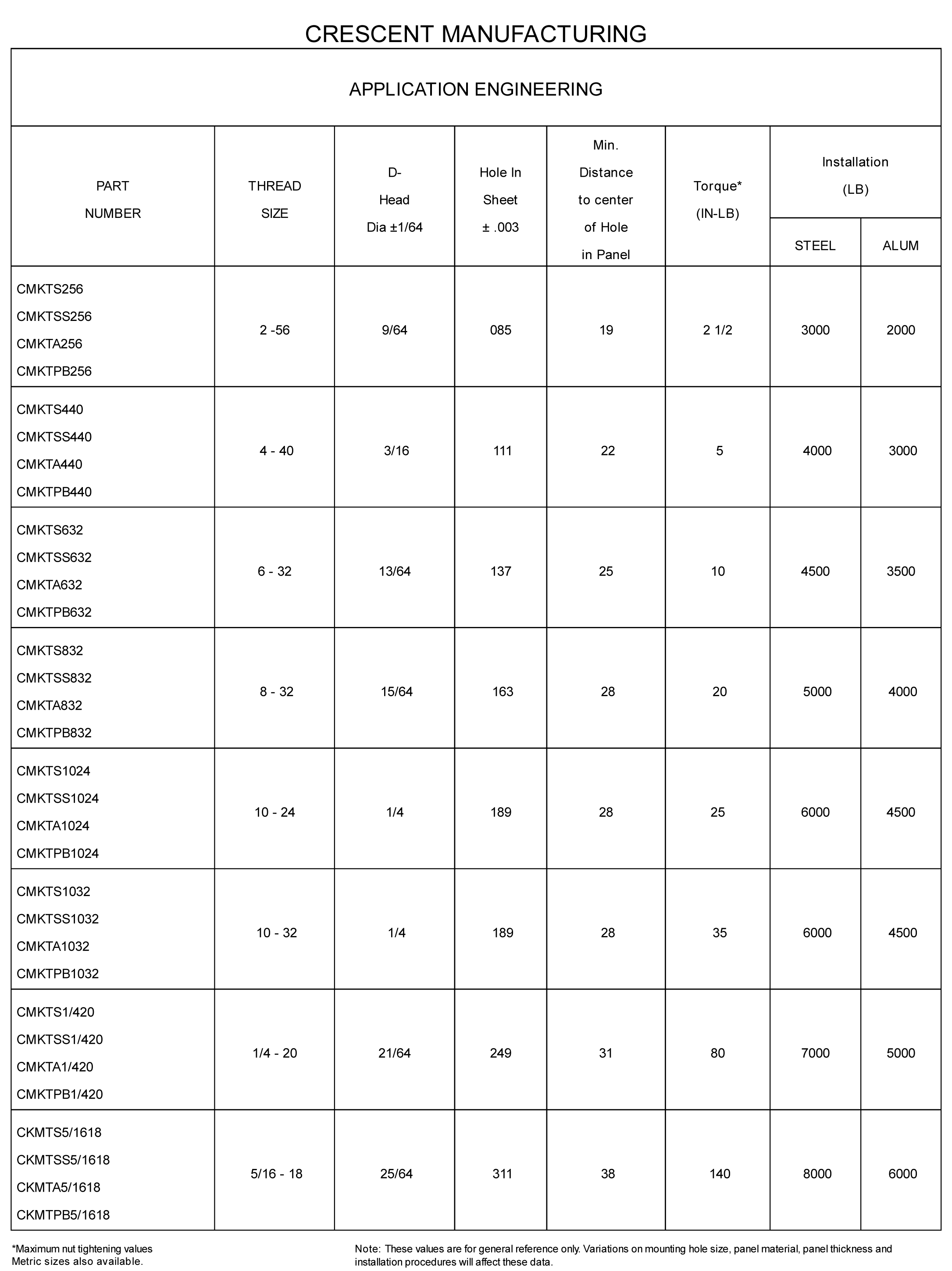

Unlike many other brands of self-clinching studs that have six serrations, the Crescent Kwik-Thred? has twelve for significantly more gripping power. Sizes range from 2 to 5/16 (as shown below) with the material listed below.

INSTALLATION

General Tooling Setup

Installation Notes: Apply only sufficient squeezing pressure to embed head of stud flush with panel. Do not use more pressure than necessary. Amount of pressure varies with panel material and size of stud. Studs install flush in sheets .040″ or thicker but will project up to .020″ in thinner sheets.

Thin Sheet Anvil (A)

For panels less than 0.060″ in thickness, with #2 thru #10 thread sizes.

For panels less than 0.093″ in thickness, with 1/4″ thread size.

Thick Sheet Anvil (B)

For panels 0.060″ and more in thickness, with #2 thru #10 thread sizes.

For panels 0.093″ and more in thickness, with 1/4″ and 5/16′ thread sizes.

| KWIK-THRED® | CAPTIVE® FASTENER | PEM® SERIES | MATERIAL | PRODUCT INFORMATION |

|---|---|---|---|---|

| CMKTS CMKTSS CMKTA | CH CHS CHA | FH FHS FHA | MILD STEEL 302SS ALUMINU | FLUSH HEAD, THREADED SELF-CLINCHING STUDS. DESIGNED FOR QUICK, EASY INSTALLATION IN PANELS AS THIN AS .040″ (1MM) |

| CMTHKTS CMTHKTSS CMTHKTPB | HCH HCHS HCHB | HFH HFHS HFHB | HARDENED ALLOY STEEL 302SS PHOS BRONZE | THICK HEAD, THREADED SELF-CLINCHING STUDS. DESIGNED WITH A LARGER HEAD TO PROJECT ABOVE THE PANEL TO PROVIDE GREATER TENSILE & PULL THROUGH STRENGTH. |

| CMKTS CMKTSS CMKTA | CH OR CHN CHS CHA | FH OR FHN FHS FHA | MILD STEEL 302SS ALUMINUM | UNTHREADED, SHELF-CLINCHING PINS. DESIGNED TO BE USED AS PERMANENTLY MOUNTED PINS. |

| CMKTPB | CKFH | KFH | PHOS BRONZE | BROACHING STUDS FOR PERMANENT MOUNTING IN NON-DUCTILE MATERIALS & PRINTED CIRCUIT BOARDS |